Sustainability

Resource-efficient by nature, EPS helps others reduce their carbon footprints, preserve biodiversity and create a more circular economy.

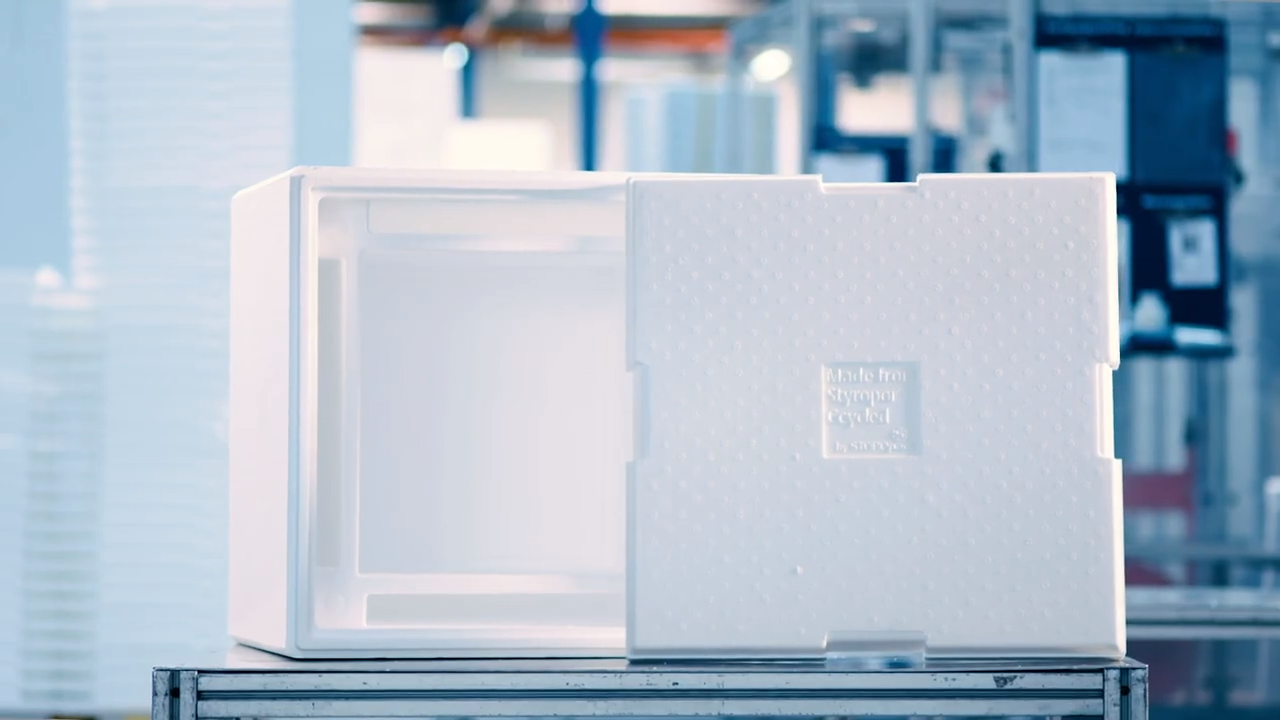

Whether by mechanical or chemical recycling, EPS can be turned into raw materials for a new generation of EPS packaging or many other goods. Some companies are now making new EPS packaging out of 100% post-consumer EPS waste.

But did you know that EPS also helps protect bees and biodiversity, reduce food waste, and contribute to the circular economy? If not, read on!

EPS Sustainability Case Studies

EPS Life Cycle

Mechanical recycling keeps the cycle going

Expanded Polystyrene can be recycled in an efficient mechanical process to manufacture a long list of secondary products from packaging to construction and other products.

The process starts when EPS is collected directly from its many commercial users or households.

Separated or sorted EPS waste can be compacted efficiently, depending on the desired feedstock for recycling. In many cases specialist, fuel-efficient trucks known as high-volume vehicles, are used for its transport. Any contaminated material like some including a now-banned flame retardant is sorted out before the process continues.

Then, EPS moulds are fed into a pre-shredder where they are cut first into palm-sized pieces, then later subjected to further grinding and setting processes. The resulting material, called “shred” can be used as an additive for the plaster and mortar industry, in seat cushions, or as a pore-forming agent in brick manufacturing, extending the life cycle of the EPS for decades.

In many countries, there is a large industry of small and medium-sized companies that specialise in recycling EPS.

See how it works in the videos below.

Chemical recycling makes EPS ‘good as new’

A chemical recycling process known as pyrolysis can convert EPS in mixed plastic waste into pyrolysis oil, which can be fed into the production of basic chemicals in place of fossil feedstock. EPS that results from this chemical recycling process is indistinguishable from EPS made from virgin raw materials.

A variety of recycling options, combined with the fact that EPS packaging generally consists of a single polymer, make EPS one of the most recyclable plastic packaging materials available.

How chemical recycling works

Comparative results of three packaging solutions in an average 6 kg European situation

Comparisons of the total life-cycle impact of the uses of different packaging materials in terms of energy use, water use, pollution and waste material volumes show that expanded polystyrene (EPS) compares favourably with polypropylene (PP) and cardboard packaging because of its energy-efficient production and light weight.

*Comparative results of three packaging solutions in an average 6 kg European situation, Pricewaterhouse Coopers, November 2011.