Why EPS?

Lightweight, shock-resistant, and an exceptional insulator, EPS is a highly versatile packaging material.

Three reasons: Versatility, Reliability and Sustainability

Expanded polystyrene is a highly versatile packaging material widely used to protect everything from electronics to bees to people: EPS is widely used in bicycle, ski and snowboard helmets, children’s car seats and life vests – applications in which both safety regulations and users demand exceptional performance.

It is also highly reliable: Lightweight, shock-resistant, and an exceptional insulator, EPS is widely used to protect high-volume goods from fresh fish, fruit and vegetables to super-cooled COVID-19 vaccines and human organ transplants during transportation.

Moreover, EPS packaging is sustainable: because it contains 98% air, it saves energy and reduces CO2 emissions during transport. It also helps reduce food waste. It is an easily recognisable material, which can thus be easily separated and sorted. Lastly, since it is made with a single polymer, it is easy to recycle into new products including new packaging, building insulation—even surfboards.

For these reasons and many more, EPS is the smart packaging choice for a wide range of packaging challenges.

Versatility

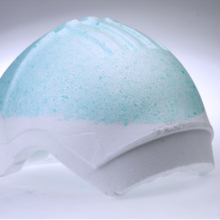

Most people think of EPS in terms of bright white, lightweight boxes that protect something that they have bought. But did you know that EPS is also used in gear such as bicycle helmets and children’s car seats?

In fact, EPS is used in many ways that people might find surprising: as an artificial seed bed for seedlings in plant nurseries, to protect bees, to save lives at sea, to provide lightweight cushioning for automobiles – even to make surfboards.

This is how EPS COVID-19 vaccine shipping works – all at ‑70° C

Reliability

If EPS has been going strong since the 1950s that’s in part because it has proved to be extremely reliable: In addition to the uses mentioned above, it’s also the packaging of choice for super-cooled COVID-19 vaccines, fresh fish and seafood and fresh fruit & vegetables.

EPS is also widely used to protect sensitive electrical and electronic equipment such as televisions and high-value white goods such as refrigerators, ovens and washing machines.

Sustainability

The best measure of the sustainability of any product is its total life-cycle impact, including its carbon footprint.

Because expanded polystyrene, or EPS, is composed of 98% air, it has an excellent sustainability profile. It uses resources such as water and raw materials – 2% polystyrene from fossil sources or from recycled EPS – efficiently in production. It is lighter than almost any alternative packaging material with similar thermal insulation and shock absorption properties during transportation. Ultimately, the sustainability of packaging materials is to a large extent determined by how well they protect the contents inside: Every product which gets broken or goes bad is waste.

Because it is so lightweight, EPS packaging reduces the carbon footprint of everything that it protects during transportation, from fresh fish and produce to refrigerators. A 2011 life-cycle analysis by PricewaterhouseCoopers* found that use of EPS packaging results in less greenhouse gas emissions, pollution and waste than cardboard, with three times less water consumption.